Band Saw - B&q

Band Saw Jiji

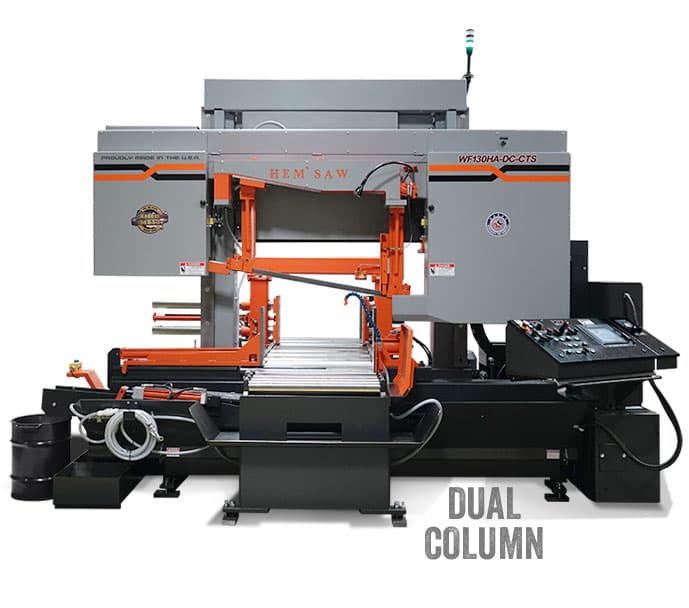

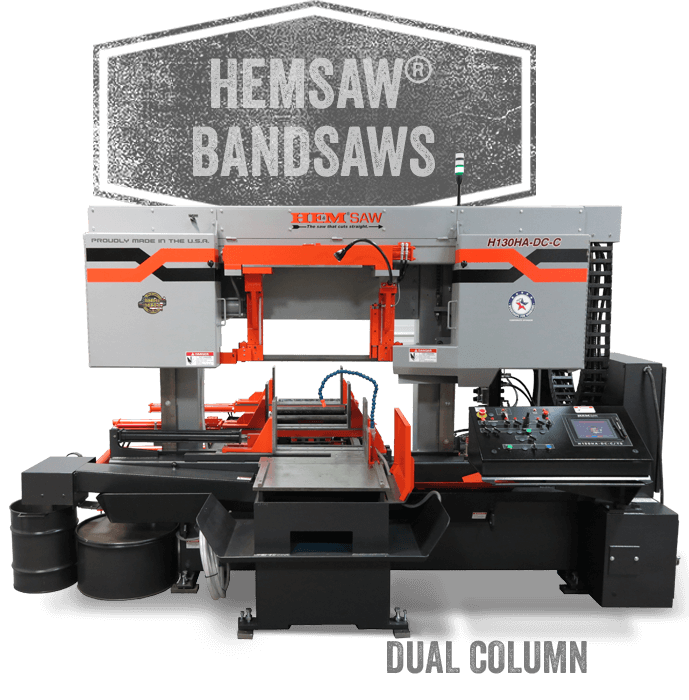

These are the most pricey type of bandsaw. These saws are ideal for contractors or professionals with commercial cutting needs.

You can work with large materials thanks to the saw's 6 inch height capacity and 13-5/8" width.